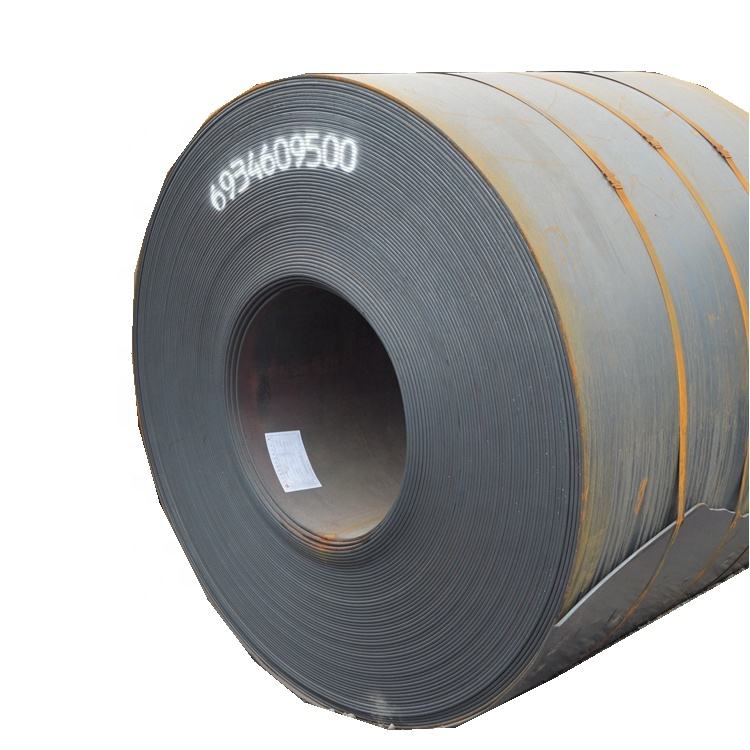

Ss400, Q235, Q345 Sphc Nhema Simbi Kabhoni Simbi Coil Simbi Simbi Hr Inopisa Yakakungurutswa Simbi Coil

Kupisa-yakakungurutswa steet/coil kubva pakupedzisa yekupedzisira inopisa simbi tambo mill kunze kuburikidza nelaminar kuyerera kutonhora kusvika kune yakatarwa tembiricha, iyo ine winder coil, simbi coil mushure mekutonhora, zvinoenderana nezvinodiwa zvakasiyana zvevashandisi, ine mutsara wekupedzisa wakasiyana (flat. , kutwasanudza, transverse kana longitudinal kucheka, kuongorora, kuyera, kurongedza uye logo, nezvimwewo) uye kuva ndiro yesimbi, flat roll uye longitudinal yekucheka simbi strip zvigadzirwa.Nemhaka yekuti zvigadzirwa zvesimbi zvinopisa zvine simba rakawanda, kusimba kwakanaka, kushandiswa nyore uye kunaka weldability uye zvimwe zvinhu zvakanakisa, inoshandiswa zvakanyanya mukuvaka zvikepe, motokari, bhiriji, kuvaka, michina, kumanikidza ngarava uye mamwe maindasitiri ekugadzira.

| Giredhi | Rank | Kuumbwa Kwekemikari(%) | ||||

| Q215 | C | Mn | Si | S | P | |

| A | 0.09~0.15 | 0.25~0.55 | ≤0.3 | ≤0.05 | ≤0.045 | |

| B | ≤0.045 | |||||

| Q235 | A | 0.14~0.22 | 0.30~0.65 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | 0.12~0.20 | 0.30~0.70 | ≤0.045 | |||

| C | ≤0.18 | 0.35~0.80 | - | ≤0.04 | ≤0.04 | |

| D | ≤0.17 | ≤0.035 | ≤0.035 | |||

| Q255 | A | 0.18~0.28 | 0.40~0.70 | ≤0.3 | ≤0.05 | ≤0.045 |

| B | ≤0.045 | |||||

| Q275 | 0.28~0.38 | 0.50~0.80 | ≤0.35 | ≤0.05 | ≤0.045 | |

Carbon simbi imhando yakajairika yesimbi iyo iri alloy yesimbi uye kabhoni.Iyo ine yakakwira kabhoni yemukati, yakaderera kunyungudika uye kusimba kukuru kana ichienzaniswa nesimbi isina tsvina.

Carbon simbi ndiyo inonyanya kushandiswa huinjiniya uye kuvaka zvinhu zvekushandisa mumaindasitiri pamwero mukuru, kusanganisira zvivakwa zvemugungwa, zvidyarwa zvemagetsi, zvekufambisa, kugadzirwa kwemakemikari uye kugadzirwa kwepetroleum nekunatsa.

Δ Hot yakakungurutswa zvinhu zviri kunyura muchoto chinotonhora chakakungurutswa uye mushure mekunhonga muasidhi.

Δ Yese mill roll inogayiwa pamushini wekukuya chaiwo une chamfering chaiyo mushure mekutanga kushanduka kushanda.

Δ Mashiti ese anotorwa mumatangi akasiyana uye mashiti akaomeswa pamushini webrashi roll usati watumirwa.

Δ Aya mashiti zvakare anealing anobva atumirwa kunotwasanura muchina wekutwasanudza nekunhonga muasidhi uye kutumira kunorongedza zvinoenderana nehukuru uye hunhu.

Δ Kuongorora kunoitwa pamatanho akasiyana.Nevashandi vane ruzivo vanochengeta kutonga kwakaringana kwese kwemukati maitiro kuburikidza nekukunguruka, annealing, pickling, kurapwa kwemarara nezvimwe.